Understanding Hazard Classes for Automotive Batteries: Compliance, Safety, and Best Practices

Introduction: The Importance of Hazard Classification for Automotive Batteries

Automotive batteries power millions of vehicles, but their chemical composition and potential hazards mean they are regulated under strict hazardous material (hazmat) classifications. Understanding which hazard class applies to your automotive battery type is essential, not only for legal compliance but also for ensuring the safety of people and the environment. This article provides a comprehensive overview of automotive battery hazard classes, explains why these regulations exist, and offers step-by-step guidance for anyone involved in the handling, shipping, or disposal of these batteries.

Hazard Classes Defined: What Are They and Why Do They Matter?

The U.S. Department of Transportation (DOT) and related international agencies classify hazardous materials into specific hazard classes based on the risks they pose during transportation and handling. Automotive batteries are typically categorized under two main hazard classes, depending on their chemistry:

- Class 8 – Corrosive Materials : Includes substances that cause severe damage to living tissue or other materials through chemical action. Lead-acid batteries and similar types fall into this class because of their sulfuric acid content, which can cause burns and corrode metals [3] [1] .

- Class 9 – Miscellaneous Dangerous Goods : Covers substances that pose hazards during transport but don’t fit into other categories. Lithium-ion batteries, commonly used in hybrid and electric vehicles, are included here because of their fire and explosion risks [1] [2] .

Understanding these classifications is critical for anyone involved in the lifecycle of automotive batteries, from manufacturers and distributors to automotive repair shops and end users.

Types of Automotive Batteries and Their Hazard Classes

Lead-Acid Batteries (Class 8)

Most traditional vehicles use lead-acid batteries. These contain lead plates submerged in sulfuric acid, a potent corrosive agent. Because of the risk of acid leaks and the potential for chemical burns or environmental harm, these batteries are classified as Class 8 hazardous materials. When damaged, improperly handled, or disposed of, they can cause serious injuries and environmental contamination [3] [2] .

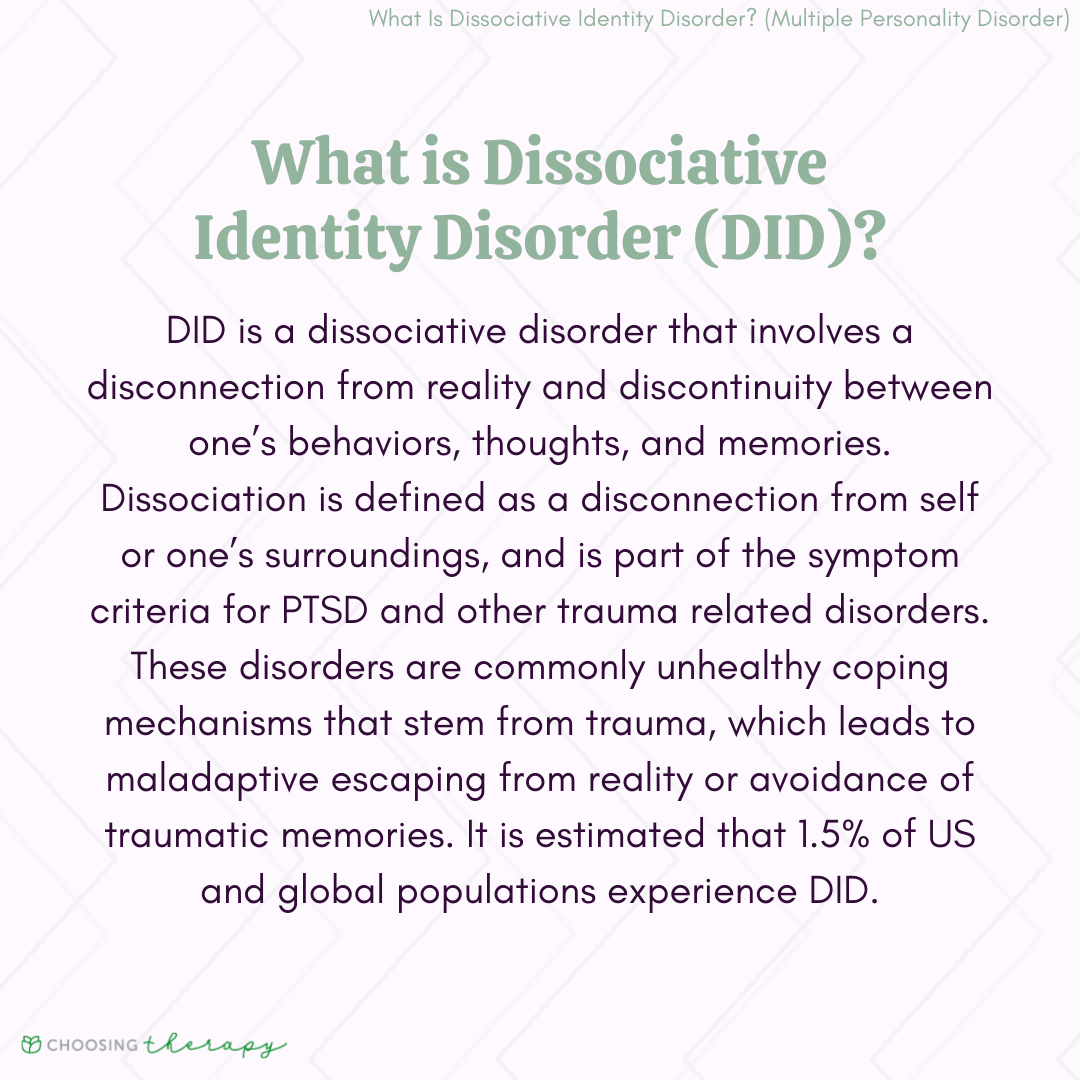

Lithium-Ion Batteries (Class 9)

Lithium-ion batteries are found in hybrid and electric vehicles due to their high energy density and long cycle life. These batteries carry risks of fire, explosion, and toxic gas release if damaged or improperly managed. As a result, they fall under Class 9 hazardous materials [1] [5] . Their risks are different from lead-acid batteries but no less serious, especially during shipping and disposal.

Source: siemens.com

Nickel-Metal Hydride (NiMH) and Other Types

Nickel-metal hydride (NiMH) batteries, used in some hybrid vehicles, are generally less hazardous but can still fall under Class 9 depending on their size and configuration. Other battery types, such as nickel-cadmium (NiCd), may also be regulated, and their classification depends on chemical composition and risk profile [1] .

Source: animalia-life.club

Real-World Examples: How Hazard Classes Affect Handling and Shipping

Consider a repair shop that ships used lead-acid batteries to a recycling facility. These batteries must be packaged in leak-proof containers, labeled with Class 8 hazardous material placards, and transported by carriers certified to handle corrosive substances. Failure to comply can result in fines, environmental harm, and personal injury [3] .

Alternatively, a business exporting lithium-ion batteries for electric vehicles must follow strict Class 9 regulations. This includes using specialized packaging, providing documentation about battery type and condition, and sometimes limiting quantities per shipment. Airlines and freight companies may have additional restrictions because of the risk of thermal runaway and fire [1] [2] .

Step-By-Step: How to Identify the Hazard Class of Your Automotive Battery

- Identify the Battery Type : Check the label or consult the vehicle manual to determine if the battery is lead-acid, lithium-ion, NiMH, or another type.

- Review Regulatory Guidelines : For U.S. shipments, consult the Department of Transportation (DOT) Hazardous Materials Table (search for “DOT Hazardous Materials Table” on the official DOT website) to confirm the classification. For international shipping, refer to the International Air Transport Association (IATA) or International Maritime Dangerous Goods (IMDG) codes.

- Assess Condition and Size : Damaged or oversized batteries may have stricter requirements. For example, leaking lead-acid batteries are more hazardous, and large-format lithium-ion batteries require additional precautions.

- Label and Package Correctly : Use required hazmat labels and certified packaging. For lead-acid, this means Class 8 labeling; for lithium-ion, Class 9. Packaging must prevent leaks or short circuits.

- Arrange Proper Transportation : Use carriers authorized to transport hazardous materials. Many carriers have dedicated hazmat departments that can provide guidance.

- Document and Track : Maintain shipping records and incident response plans in case of leaks, fires, or regulatory inspections.

If you are uncertain about your battery’s classification or requirements, contact your local environmental agency, recycling center, or vehicle manufacturer for guidance.

Safe Disposal and Recycling: What You Need to Know

Proper disposal of automotive batteries is not only a regulatory requirement but also an essential environmental responsibility. Lead-acid batteries are almost universally recyclable, and most auto parts stores, service centers, and recycling centers accept them. Always call ahead to confirm acceptance policies and any fees.

Lithium-ion batteries require special recycling processes due to fire and toxicity risks. Some electric vehicle manufacturers and certified recycling programs offer take-back services. To find a local recycling facility, you can search for “automotive battery recycling near me” or visit the official website of your municipal waste authority.

Common Challenges and How to Overcome Them

Challenge: Determining the correct hazard class for a less common or mixed-chemistry battery.

Solution: When in doubt, consult the product manufacturer, review the battery’s Safety Data Sheet (SDS), and check the DOT Hazardous Materials Table. Many manufacturers also have dedicated support lines for regulatory questions.

Challenge: Complying with varying state, federal, and international regulations.

Solution: Regulations may differ across jurisdictions. For interstate or international shipments, always confirm with the relevant regulatory agency (DOT, EPA, IATA, IMDG) and make use of their official resources.

Challenge: Safe storage and emergency response.

Solution: Store batteries in cool, dry locations away from incompatible materials. Maintain spill kits, fire extinguishers, and emergency contacts. Train staff on proper handling and response procedures.

Alternative Approaches and Best Practices

Some organizations invest in battery management systems and compliance software to track regulatory requirements and ensure safe handling. Partnering with certified hazmat carriers and recyclers reduces risk and liability. For large fleets or commercial operations, consider designating a compliance officer or working with an environmental consultant to stay current with evolving regulations.

Summary and Key Takeaways

Automotive batteries are regulated under hazardous material laws due to the risks posed by their chemical contents. Lead-acid batteries are classified as Class 8 (corrosive), while lithium-ion and some other advanced batteries fall under Class 9 (miscellaneous dangerous goods). Correct classification is critical for safety, legal compliance, and environmental responsibility. When handling, shipping, or disposing of automotive batteries, always verify the battery type, follow regulatory guidelines, and consult official resources or industry experts if you are unsure.

References

- [1] LAX Freight (2024). Automotive Batteries are an Example of Which Hazard Class.

- [2] Manly Battery (2023). Automotive Batteries Are an Example of Which Hazard Class.

- [3] FreightRun (2023). What Hazard Class are Automotive Batteries.

- [4] Batteries Inc. (2023). Hazardous Materials Classification for Batteries.

- [5] Royalty Speed (2022). Automotive Batteries Are in Which Hazard Class?

MORE FROM oncecoupon.com